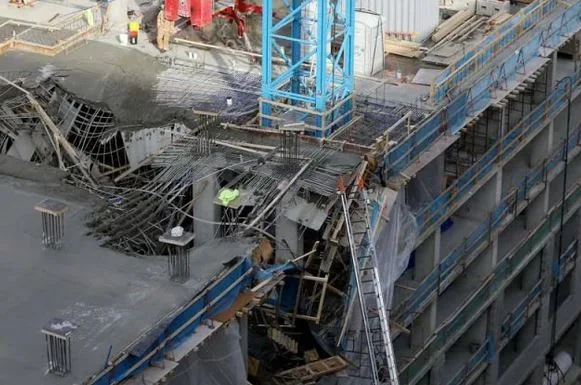

Formwork Failure

Construct a concrete building requires formwork to support it. Specific types are engineered structures required to sustain loads such as building materials, fresh concrete, vehicles, movement load of workers, various impacts, and even wind pressure.

|

| Figure – 1: Concrete Formwork Failure |

Without failure or too much deflection, the forms must bear all the burdens applied. The formwork should be conceived under the fundamentals of efficiency, health, and economy. Frequently used in conjunction the words formwork and falsework.

Formwork is the support system for newly poured concrete which requires the sheathing, which is in addition to all supporting members in contact with the concrete, and the necessary bracing, hardware.

This Falsework is a temporary structure built to support work in building progress. The Falsework can be the momentary aid for steel placement systems.

Formwork method in the building industry plays a leading role in the design of reinforced concrete cast structures in situ. Lifecycle and service are the basic diverse equipment within the formwork system.

There are many factors which could contribute to formwork failure during and after concrete placement. Improper bracing can cause formwork failure, since formwork system no longer supports the weight of fresh concrete. Unanticipated incident will result in the member failing and subsequent overloading or misalignment of other members resulting in the complete formwork system failing.

Causes of Formwork Failure

- Inappropriate stripping and shore exclusion,

- Lack of knowledge to specify the formwork,

- Beneath a muddy field poor surface,

- Shaking or vibration

- Lack of bracing,

- Lack of concrete placement plans,

1. Inappropriate stripping and shore exclusion

Early stripping of forms and careless practices in re-shoring can lead to formworks failure and complete failure of specifically in multistory building where progressive collapse is highly probable.

Occasionally premature striping causes the partly cured concrete to decay. This leads to the creation of cracks and causes maintenance problems. Insufficient spacing and reshore sizes can lead to a collapse in the shape and damage of the concrete framework during construction.

2. Lack of knowledge to specify the Formwork

Errors in assembly such as inadequate fastening, lack of tightening onto the locking devices on metal shorelines, inadequate provisions to prevent the rotation of beam shapes where slab shapes frame on one side and insufficient anchorage against upliftment for inclined shapes and a failure of tightening or binding on corners may cause formworks to fail even though their design is carried out in the optimal way. Thus the professional and trained work under great supervision shall install the formwork method.

3. Shaking or vibration

Vibration and impact due to traffic transmission, workers’ movements and coffering machinery and concrete consolidation vibration, may break the supporting shores or shape device jackets and cause a complete shape failure.

4. Lack of bracing

Lack of cross bracing and horizontal shore bracing are common causes of formwork failure. The explanation is that inadequate bracing produces lateral strength and thus lateral deformation of supporters.

If failure occurs at some stage, the failure will cause the collapse to stretch and multiply the damage to a large portion of the structure.

4. Inadequate Control of Concrete Placement

Failure to adequately control the pace and order of concrete placing on horizontal formwork causes unbalanced loadings and consequent formwork failures.

Accordingly, concrete temperature, concrete chemistry, vertical placement rate of concrete, and concrete vibration are factors that affect the production of lateral pressure acting on the surfaces.

When concrete temperature decreases during building activities, the concrete placement rate needs to be lowered in order to prevent a accumulation of lateral overloading of the formworks.