Basic Civil Engineering

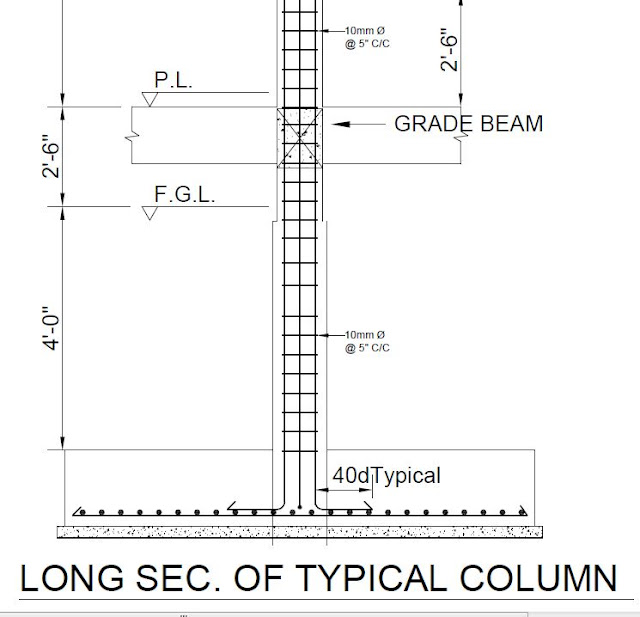

Complete Guide to Column Design Rule as per ACI Code for Reinforced Concrete

Introduction to the column design as per ACI 318 code Column design is the most important part of reinforced concrete structures of residential, commercial, or …

Read moresoftware

E-books

BNBC 2020 pdf download | Bangladesh National Building Code 2020

BNBC 2020 pdf download. Bangladesh National Building Code 2020 BNBC 2020 pdf download, AS A CIVIL ENGINEER, IT’S VERY IMPORTANT TO KNOW ABOUT BUILDING DESIGN …